Experience the essence of personalized luxury with us. Collaborate with our skilled artisans through our custom design process to craft a truly distinctive piece that mirrors your individual style and preferences.

Creating Custom Jewelry

Our specialized design staff collaborates directly with you, taking the time to understand your individual preferences, thoughts, and aspirations for your jewelry piece. We work together to modify the concept until it precisely expresses your vision and desires, using comprehensive talks, sketches, and ongoing input.

Once the design has been finished to your satisfaction, our highly talented artisans methodically bring it to life, infusing every aspect with accuracy and attention. Our method is more than just making a piece of jewelry; it's about producing a symbol that represents your uniqueness, style, and important occasions. Each work demonstrates our dedication to excellence and our enthusiasm for turning your ideas into magnificent realities.

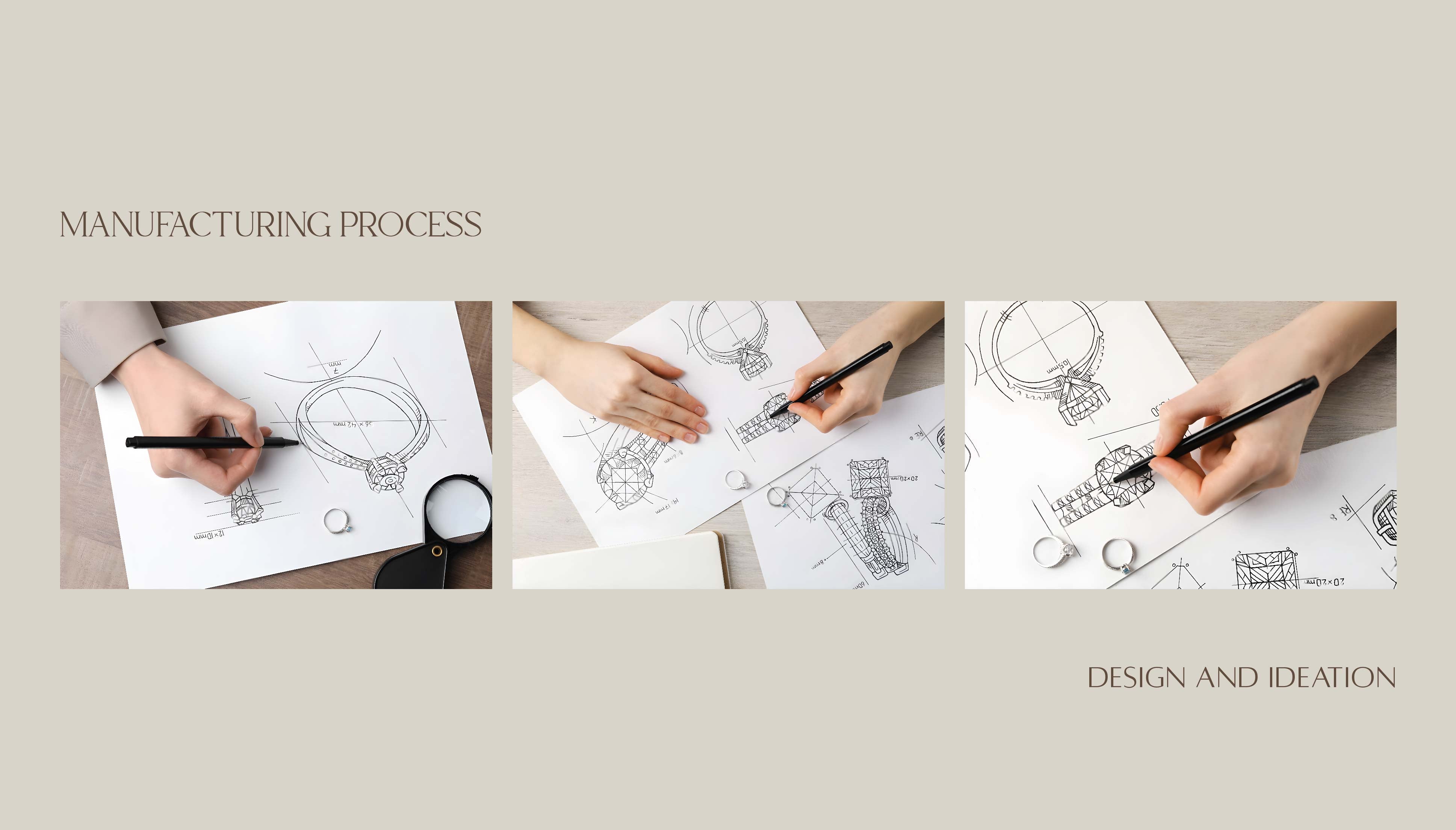

Design

In order to produce a unique piece, the very initial step is to create a design. It is a stage wherein the designer develops an idea for the design, evaluates the idea and translates it into reality.

CAD

Once a design is conceptualized in the mind of the jewellery designer, it is drawn on paper and then into the system. This process of constructing a design into the system is facilitated through Computer Aided Designing technology.

Rapid Prototyping

Once the CAD design file is ready, it is transferred on 3D Rapid Prototype system. This system works on the principle of Direct Light Projection Technology. The resin model is created using 3D Rapid Prototyping system (RPT) which is fully functional

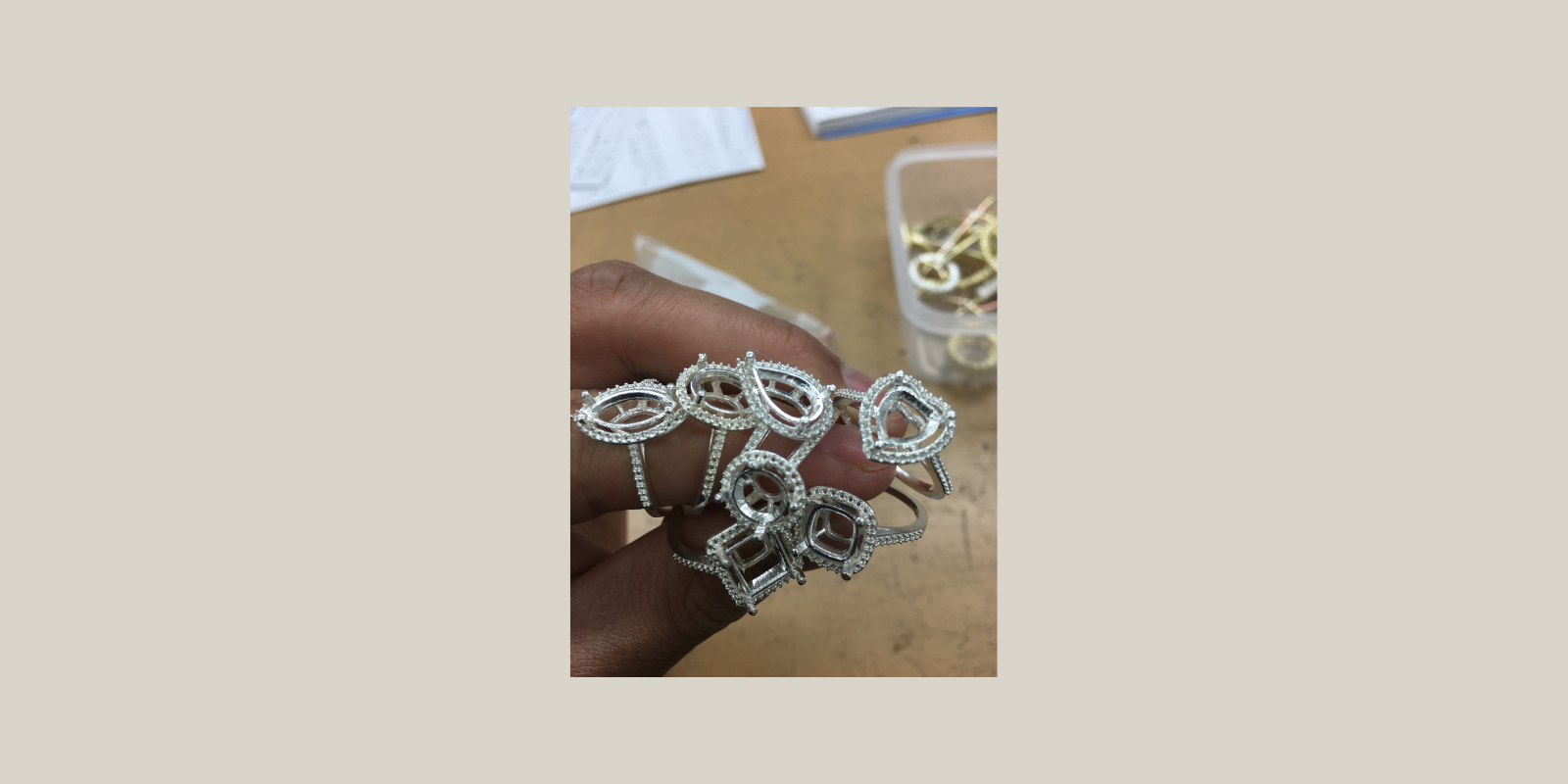

Model Making

Resin output from CAM is then converted into silver model by using casting process.

The silver model is a master design that is copied to make many similar pieces of jewellery. The silver model is used to create the rubber Mould from which all subsequent pieces are made.

Rubber Mould

Mould making is an integral part of the production process. It helps in creating multiple pieces of jewellery of the same design.

These designs remain protected and embedded in the mould forever and it is possible to create replicas of the same in future. There are different types of materials used for mould making like natural rubber, silicone and metal. The method used for mould making is called “Vulcanizing”

Waxing/Wax Tree

This step involves the production of wax pieces from the rubber moulds made from the silver master. The rubber mould is placed on the commercial wax injector machine. Molten wax is pressure injected into the mould cavity to create wax models for casting.

The process of soldering the wax pieces on a wax stem is called “treeing”. A sprue is attached to each piece which in turn is attached with the stem.

The sprue makes an angle of approximately 45 degrees with the stem. The tree is such that the heavier items are at the bottom of the tree and the lighter ones are at the top.

Casting

Casting is a very complex process and requires utmost skilled and experienced casters for the desired final product. The wax tree is placed in steel flask which is then occupied with a slurry of chemical powder which solidify in an hour.

The flask is than heated in an electric furnace which melts the wax leaving behind a cavity of tree. Molten metal is then poured into the flasks, allowed to cool, then demolished to reveal the Jewellery in casting form.

Grinding

Once the raw casting is clipped off from the casting tree, it has a tiny nub leftover at a place where the gold piece was attached to the sprue.The polisher grinds off this nub using the motorized grinding machine, which acts as an abrasive to smooth the surface of the gold piece/jewellery.A final polishing is then done by holding the piece against a spinning grinding wheel to achieve a smooth surface.

Polishing

Polishing offers a neat finish and enhances the value of a piece. Polishing involves three steps, tumbling, pre polishing, and ultra-cleaning. Jewellery pieces with diamonds require pre polishing before the diamond is set.

This is because once the diamonds are set the area below the diamond portion cannot be polished and may affect the shine of the diamond.

Final Steps

Stone Setting

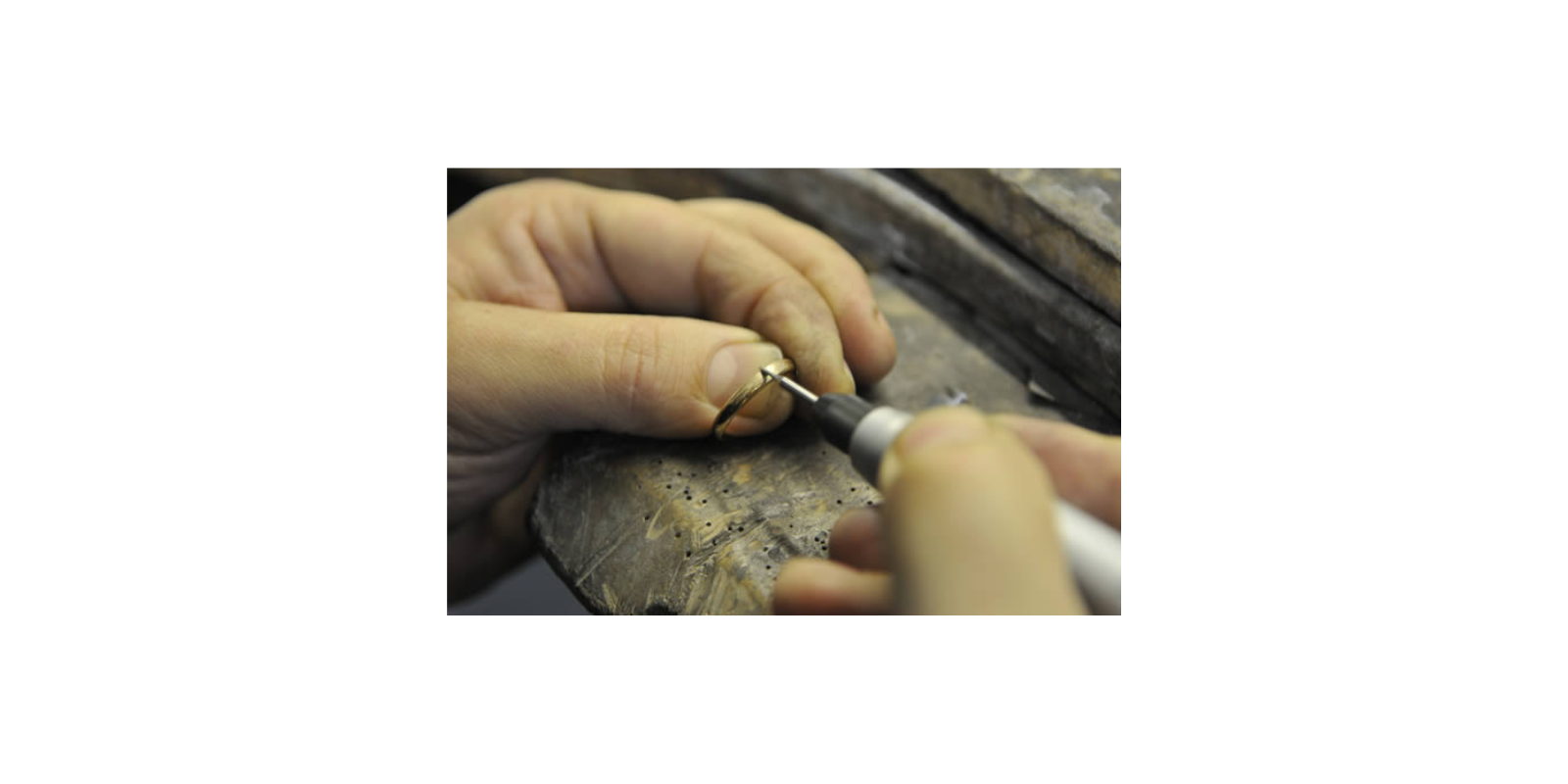

Stone setting is the art of securely setting or attaching gemstone in the jewellery. Different types of setting are used to create varied designs; sometimes even combination of two setting is also used to make a piece look more appealing.

The different types of setting are prong, plate prong, pave, pressure, bezel, bead, flush, fishtail, invisible, miracle plate and channel.

Rhodium Plating

Rhodium is a sparkling white coloured precious metal. When a piece of jewellery is plated with Rhodium, it gives a white reflective appearance and provides the piece of jewellery better resistance to scratches and tarnish.

It is used on yellow gold for creating visually appealing patterns and designs. The use of Rhodium plating on white gold is meant for adding whiteness to the gold, since white gold is not so white in its original and pure form.

Stone Setting

Stone setting is the art of securely setting or attaching gemstone in the jewellery. Different types of setting are used to create varied designs; sometimes even combination of two setting is also used to make a piece look more appealing.

The different types of setting are prong, plate prong, pave, pressure, bezel, bead, flush, fishtail, invisible, miracle plate and channel.

Rhodium Plating

Rhodium is a sparkling white coloured precious metal. When a piece of jewellery is plated with Rhodium, it gives a white reflective appearance and provides the piece of jewellery better resistance to scratches and tarnish.

It is used on yellow gold for creating visually appealing patterns and designs. The use of Rhodium plating on white gold is meant for adding whiteness to the gold, since white gold is not so white in its original and pure form.

Quality Control

Quality control (QC) is a procedure or set of procedures intended to ensure that a manufactured product or performed service adheres to a defined set of quality criteria or meets the requirements of the client or customer.

Quality Control

Quality control (QC) is a procedure or set of procedures intended to ensure that a manufactured product or performed service adheres to a defined set of quality criteria or meets the requirements of the client or customer.